At the 2023 4C Health, Safety & Environmental Conference, Emerson’s Lara Rabbath presented Decarbonization with Steam Methane Reforming for Blue Hydrogen Production.

The primary method for blue hydrogen production is mainly from natural gas (methane), using steam methane reforming (SMR) and carbon capture for decarbonization. The hydrogen recovered from the SMR process is commonly used as a feedstock for oil refining, fertilizer, or chemical production. Learn more about the challenges and offered solutions associated with SMR.

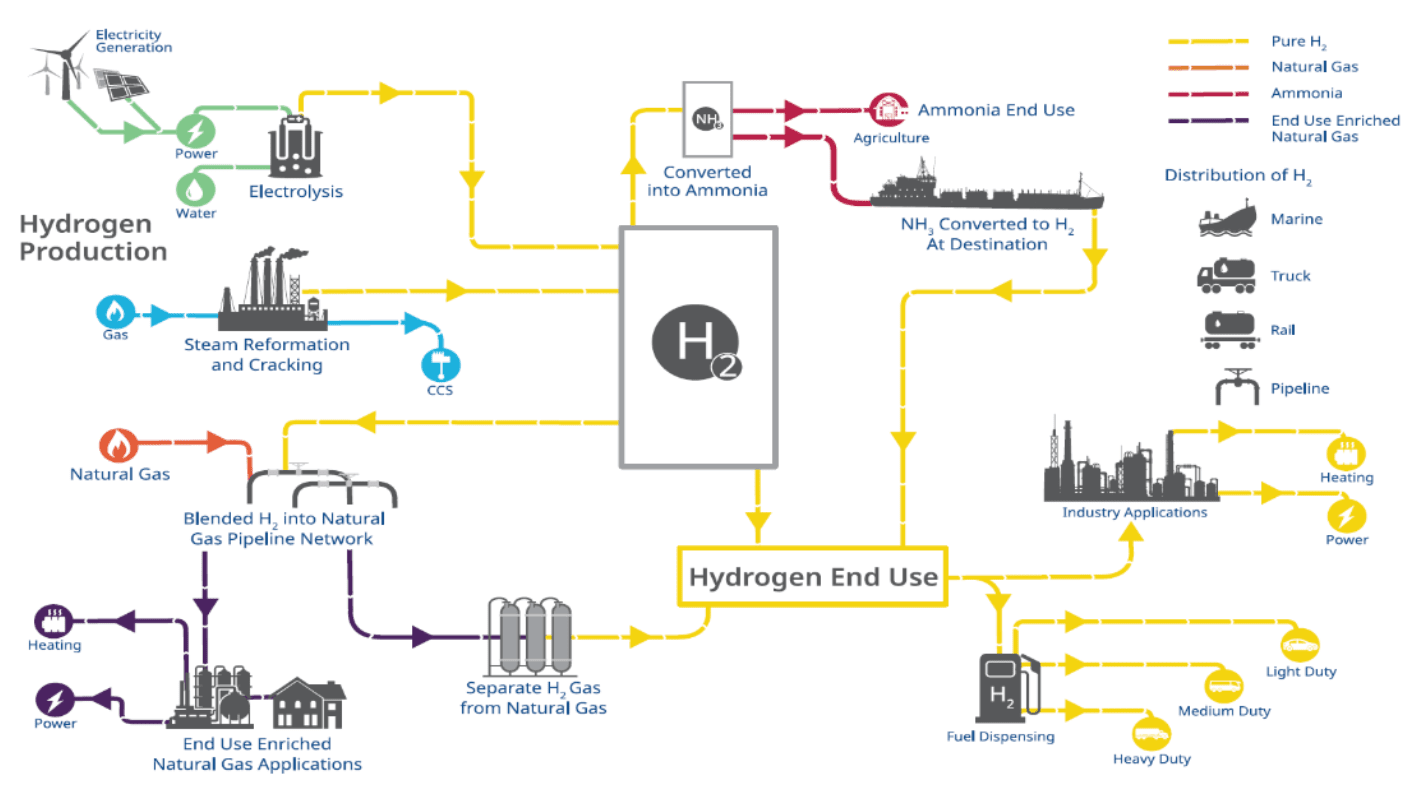

Lara opened by sharing how Emerson has technologies & solutions across the hydrogen value chain from production through distribution and dispensing. These technologies and solutions help support the need for expanded production and lower-cost distribution.

She noted that global hydrogen demand is expected to reach almost $12 trillion by 2050. This demand will create opportunities for countries with large natural gas reserves to export clean hydrogen. Feedstock such as natural gas has been widely explored to produce grey hydrogen (hydrogen produced without capturing and sequestering the CO2 emitted during operation).

Natural gas has a high percentage volume of methane, which is a reliable source of hydrogen. Its availability poses little or no challenges to hydrogen production in jurisdictions around the world where it is abundant, including the USA and Canada. The production of natural gas in these countries significantly impacts global use.

Refineries consume most of the hydrogen supply of all industrial sectors, at 57%. Of this percentage, 65% of hydrogen demand in refining is met by hydrogen supplied as a byproduct of the heavy naphtha reforming process. The balance of hydrogen required for hydrotreating, hydrocracking, and isomerization comes from the steam methane reforming (SMR) process. Outside of refining, hydrogen is consumed in processes to produce ammonia, methanol, and direct-reduced iron in the steel industry.

Given that the SMR process and other hydrogen production processes, such as autothermal reforming (ATR) and partial oxidation (POX), produce CO2 as a byproduct, coupling it with carbon capture utilization and storage (CCUS) improves the decarbonization profile. SMR and ATR differ in how heat activates the endothermic steam reforming reaction. In SMR, the catalyst is contained in tubes heated by an external burner. In ATR, a portion of the natural gas is burned to raise the temperature of the process gas before it contacts the catalyst.

From an energy use standpoint, the switch from fossil fuels to hydrogen creates many challenges, such as metal embrittlement from hydrogen, combustion invisibility, and increased NOx emissions. Some ways to address these challenges include increased sensors, flame detectors, and instrumentation. For example, gold-coated diaphragms in pressure measurement devices can avoid hydrogen diffusion into the diaphragm affecting the accuracy and stability of the measurement.

Download the Advanced Measurement Solutions Enhance Blue Hydrogen Production eBook for more on ways to optimize hydrogen production from steam methane reforming processes.

The article above was pulled on April 7, 2024 and is from the Emerson Automation Experts Blog posted by Jim Cahill, Chief Blogger and may be accessed through the following link: Hydrogen Production with Steam Methane Reforming and CCUS (emersonautomationexperts.com)

Associated Steam, Air and Hot Water is the Mid-Atlantic’s premier Manufacturer’s Representative for all your Heat Exchange and Fluid Specialties requirements including Airside, Filtration, Flow Measurement, Hot Water, Valve and Steam products. Associated provides total solutions in steam and condensate, heat transfer, hot water and humidification in Delaware, Maryland, New Jersey, Pennsylvania, northern Virginia and northern West Virginia. Associated Steam is a proud to offer products under the Pennsylvania COSTARS-8 contract.

At Associated Steam, Air & Hot Water we understand that the success of any project depends upon an understanding of the facility needs, optimum selection and design of the system, and reliable performance of the system equipment. Established in 1954, our team offers over 200 years’ industry experience, with staff ranging from Engineers to Contractors. We interrelate with consulting engineers, contractors, end users and maintenance staff to ensure your satisfaction. Associated’s body and depth of experience makes us the ideal partner for all of your Steam, Air and Hot Water needs.